POSI-TIES

BLOCK-TIES

FRAME-TIES

WING-TIES

CHAIR SPACERS

POSI-TIES

DESCRIPTION:

Posi-Ties are moulded from black Polypropylene in various lengths, with a central portion either flat or in the form of a diamond, which tapers at each end to a flat rectangular section terminating in a wide fish-tail, incorporating keying ridges. For cavity walls, the central portion has collars designed to prevent moisture passing along the tie when bedded in position. For increased strength, the ties are available in black nylon.

USE:

Posi-Ties are for use as wall ties in conventional masonry walls with or without cavities in substitution for metal ties. The ties are NON-CORROSIVE.

ASSESSMENT:

1. In the opinion of various South African authorities, the ties are suitable for this purpose.

2. The shape of the ties prevents the passage of water along the tie and hence across the cavity.

3. The ties can withstand intermittent loading such as may be imposed by wind pressure on the walls.

4. The durability of the ties will not be impaired by contact with mortar admixtures, or conventional

cavity insulation materials and they will have a SERVICE LIFE OF NOT LESS THAN 60 years.

5. The ties are not subject to moisture movement and the small thermal movement experienced in

practice will not affect their performance.

6. When bedded in mortar, the pull-out strength exceeds the tensile a strength of the tie.

7. A cavity wall consisting of two 100mm thick leaves of brickwork incorporating Posi-Ties will have a

FIRE-RESISTANCE PERIOD OF 6 HOURS when non load- bearing and at least two hours when load-bearing.

INSTALLATION:

Posi-Ties should be built into the bed joints of masonry, care being taken to place them horizontally or with a slight fall to the outer leaf of the wall, at a maximum spacing of 900mm horizontally an 450mm vertically. The spacing may be varied provided that the number of ties per unit area is not decreased. In severe exposure conditions the horizontal spacing of Posi-Ties must be reduced to a maximum of 450mm.

Normal precautions must be taken to prevent mortar droppings impairing the functioning of the drip.

The structure of brickwork or blockwork in which the ties are incorporated must be designed and/or constructed to comply with SABS0164

DESCRIPTION:

Block-Ties are moulded in the form of a “T” from black Polypropylene. The top is formed with a central triangle, to which wide fish-tails are attached. The base of the T consists of a 140mm centre portion terminating in a triangle. The triangle and fish-tail sections incorporate keying ridges.

BLOCK-TIES

USE:

Block-Ties are used for securing external walls of Block or Brick to the internal wall in substitution of brick-force metaties/mesh, particularly in low-cost housing. The Block-Ties are NON-CORROSIVE.

ASSESSMENT:

The Tie ensures a strong bond between the masonry walls.

INSTALLATION:

Block-Ties should be built into the bed joints of masonry, care being taken to place the top of the T vertically on the external wall directly opposite the central point on the internal wall at a maximum spacing of 400mm vertically in unstable conditions, the vertical spacing should be reduced.

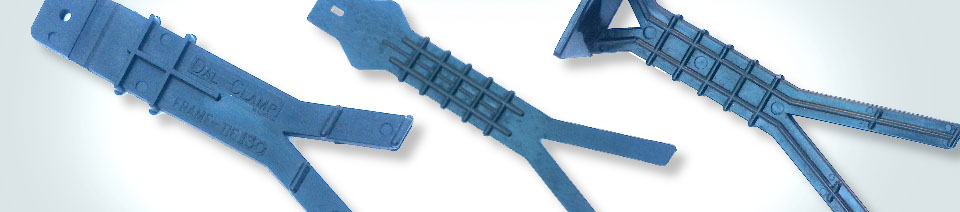

FRAME-TIES

DESCRIPTION:

Frame-Ties are moulded from black nylon in various lengths with a fixed or flexible hinge section at one end, a flat central portion and terminating in a wide fish-tail at the other end. The central portion incorporates ridging which has a dual function as a moisture barrier or as keying ridges.

USE:

The ties are NON-CORROSVIE and are an excellent substitute for hoop-iron. Frame-Ties are used for fixing of:

a. Brick/Block to concrete

b. Brick/Block to Brick where wall ties have been omitted or needing to be replaced due to corrosion

c. Brick/Block to timber

d. Brick to Steel

ASSESSMENT:

1. The Ties have been approved by various South African authorities and have a breaking strength in excess of 1.6kn and a compression strength of greater than .5kn.

2. The ties absorb limited moisture which enhances its impact strength.

3. The ties will not shear.

4. The ties revolutionary hinge gives sufficient flexibility to allow differential movement between the two structures.

INSTALLATION:

Block-Ties should be built into the bed joints of masonry, care being taken to place the top of the T vertically on the external wall directly opposite the central point on the internal wall at a maximum spacing of 400mm vertically in unstable conditions, the vertical spacing should be reduced.

INSTALLATION:

Frame-Ties are suitable to be shot-fixed to either masonry, concrete or steel. In the case of fixing to timber, the use of brass screws is recommended. The spacing of frame-ties is as directed by the architects and engineers, based on the particular application concerned.

WING-TIES

DESCRIPTION:

Wing-ties are moulded from black Polypropylene with rigid hinge section at on end, a flat central portion and terminating in a wide fish-tail at the other end. The central portion incorporates ridging which has a dual function as a moisture barrier a as keying ridges.

USE:

Wing-Ties are used for fixing of Door Frames and Window Frames into Brick/Block walls. The Wing-Ties are NON-CORROSIVE and are an excellent substitute for metal ties.

ASSESSMENT:

The ties have been approved by various South African Authorities. The ties’ revolutionary hinge gives sufficient flexibility to allow differential movement between the two structures.

INSTALLATION:

It is recommended that the Wing-Tie screwed to the window frame or door jamb at spacings not greater than 900mm. It is recommended that brass screws should be utilised for the fixing of Wing-Ties.

CHAIR SPACERS

DESCRIPTION:

Chair Spacers are used for horizontal reinforcement such as suspended slabs, beams etc. Open structure ensure concrete flow. Minimum formwork contact. Well developed for heavier steel reinforcing..

SIZE: COLOUR:

25mm Black

30mm Green

PRODUCTS

All right reserved Industrial Construction Components (Pty) Ltd

Tel - 011 0253 762

Fax : 0862187999

Mobile : 083 253 7087

Email: info@ic2.co.za